The electrical power industry faces numerous challenges on a daily basis. Electromagnetic interference to extremes in temperature; providing safe and reliable electricity to our homes or workplaces, power companies depend on a multitude of systems. In order to help protect their employees from dangerous high voltage while maintaining clear communication, many power companies choose fiber optic cable to connect devices in their monitoring and control systems.

Benefits of Optical Fiber

In order to overcome communications obstacles, optical fiber products are used in communication with protection, monitoring, and control devices. Optical fibers’ intrinsic EMI/ RFI immunity makes it ideal for harsh electrical environments. Additional benefits of optical fiber include its easy field connector termination, via the OFS Crimp and Cleave Termination system, easy testing with visible light, damage resistant cable, and electrical isolation. Events such as a ground fault or very high currents cause a difference in electrical potential from one location to another. This change in potential can damage equipment and injure people. Optical fiber provides the necessary electrical isolation to drastically reduce the risks to people and equipment.

The Role of Relays

A relay is used to sense electrical conditions and rapidly trip a breaker to protect people, property, and the power system. The combination of the relay and optical fiber provides internal diagnostics so that the relay can remain in service without interruptions for periodic testing. Although the primary function of the relay is protective in nature, the relay includes automatic control to restore service, metering and demand metering reports, sequential event reports, and event reports with fault type and location and oscillographic data snapshots.

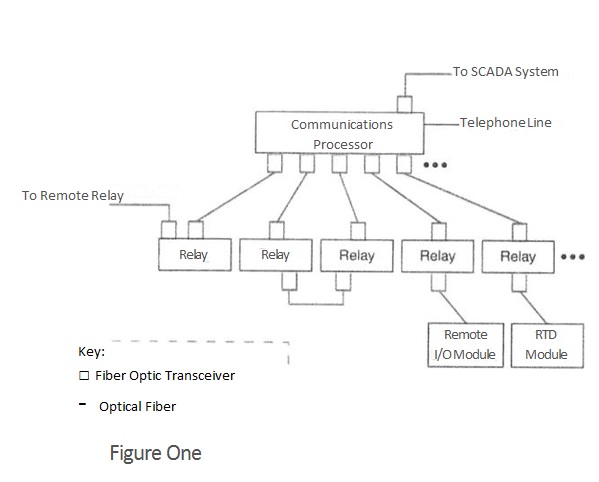

In Figure one, you see a diagram of a protection, monitoring, and control system, typical of the thousands of substations that use relays, communications processors, and optical fiber transceivers. These links are the mechanism to retrieve data from the relays, and provide direct control and instructions to the relays. Each link between a relay and a communications processor uses two optical fibers.

Protecting Motors and Power Lines

Electric motor manufacturers embed resistance temperature detectors (RTDs) in their motors to sense the temperature of the electrical windings. A RTD has built-in fiber optic ports to connect to a motor-protection relay using a fiber optic cable. If insulation of the motor winding fails, damaging currents can flow through the RTD wiring. The optical fiber link insulates the relay and the rest of the protection and control system from the RTD wiring. The relay also has valuable monitoring and reporting functions to help prevent process outages because of motor failures. Often, the motor relays are connected to an I&C system with optical fiber.

Protection, monitoring, and control systems are important in the electrical power industry. You have now been able to see the role optical fiber can play in it and how it can benefit your company with its reliable connection capabilities.

By,

Michael Steinberg